Equipment use.

Used for gluing the front and rear door panels of various steel and stainless steel doors such as anti-theft doors/fire doors/medical doors/purification doors.

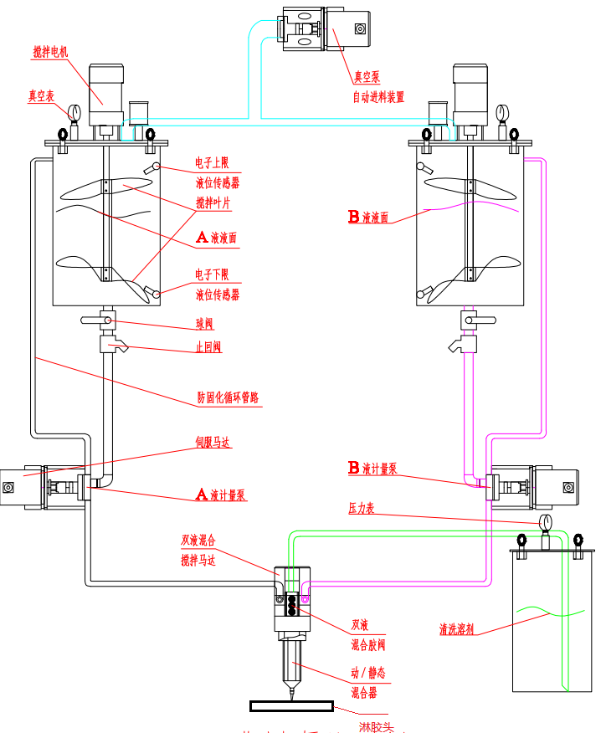

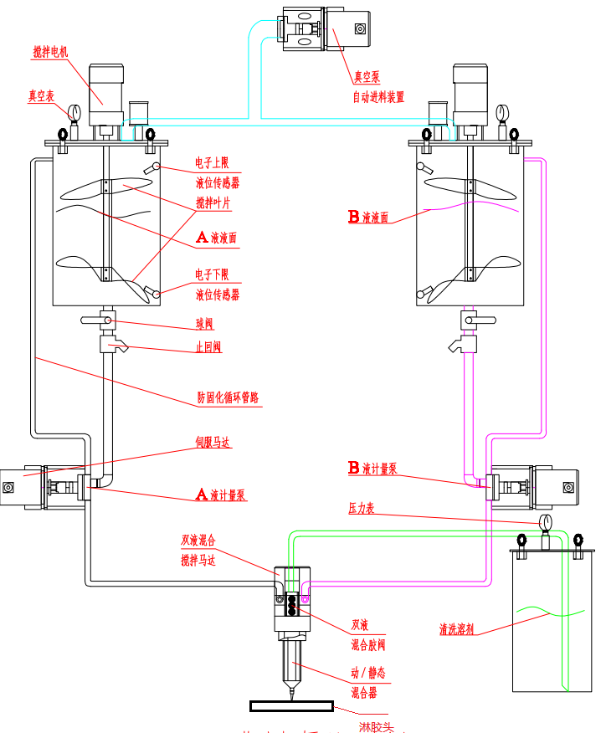

Working principle

After stacking the main agent raw material barrel and the double curing agent large rubber barrel, they are transported to the material discharging insulation warehouse with heating function, and then the glue is stably discharged through the servo glue pump, high-sensitivity glue valve mixing pipe mixing, high-precision glue dispensing head, and servo The shaft cooperates with the assembly line to evenly and flexibly spray glue, forming a uniform and continuous layer of glue.

feature of product

● CNC adjustment, the glue is mixed more evenly and glue is saved at the same time;

● Automatic glue dispensing, glue dispensing is more uniform, and it is not easy to leak glue or less glue;

● Fully automated operation, a general worker can operate it;

Technical Parameters

|

Technical Parameters

|

參考指標

|

|

Feeding plate thickness

|

(0.5-50) mm, customized according to customer needs

|

|

Feeding plate width

|

(300-1200) mm, customized according to customer needs

|

|

Feeding plate length

|

(500-3000) mm, customized according to customer needs

|

|

Glue head width

|

240mm

|

|

Production speed

|

(0-8)m/min

|

|

monitor rate

|

4.5kw

|

|

control method

|

PLC control system

|

|

Enter air pressure

|

0.4-0.8MPA

|

Random information

|

serial number

|

name

|

quantity

|

備注

|

|

1

|

Shipping list

|

1 serving

|

|

|

2

|

Acceptance report

|

1 serving

|

|

|

3

|

user's Guide

|

1 set

|

|

|

4

|

Electrical schematic diagram

|

1 set

|

|

Cooperation required from the user

1. Power supply: 380V, 50HZ, voltage fluctuation is -5% ~ +10%; when the voltage fluctuates greatly, the user must be equipped with a voltage stabilizer, otherwise the low-voltage electrical appliances will be in an abnormal working state, and the life of the electrical components will be reduced or Problems such as damage, scrapping of processed products, stoppage of work caused by motor alarm, damage to computer hard disk, etc.

2. Air source: output 0.6Mpa or above, dry and clean compressed air, air supply volume 0.3 cubic meters/minute; if the air is not dry enough, the user should be equipped with a cold dryer, otherwise water will enter the pneumatic parts and cause the piston friction resistance to change. Large, worn sealing rings lead to air leakage and other problems. Especially in winter, they are prone to freezing, leading to increased damage to pneumatic components.

3. Ambient temperature: 0°C ~ +40°C; below 0°C, parts that may contain water such as oil-water separators and gas tanks will freeze. The lubricating oil will be too viscous due to the low temperature, affecting the lubrication effect. , resulting in component damage or failure.

4. Environmental humidity: relative humidity 20~80%RH (non-condensing).

5. Stay away from strong vibration sources and electromagnetic interference; if the distance is too close, the user must be equipped with a filter, otherwise it will cause problems such as computer screen flashing, LED light flashing, driver alarms, encoder abnormalities, or interference with other nearby equipment.

6. An environment with less dust and no harmful and corrosive gases.

7. It is forbidden to cut off the power when the equipment is working, and keep the voltage stable.