Equipment Usage

Used for one-time hole forming and frame shaping of various steel and stainless steel door frames, such as anti-theft doors, fire doors, medical doors, purification doors, etc., including hinge frames and lock frames, and cutting them according to length and cross-sectional requirements.

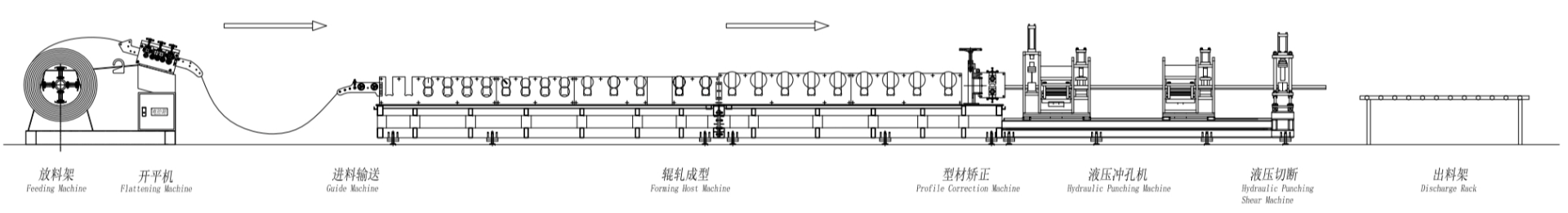

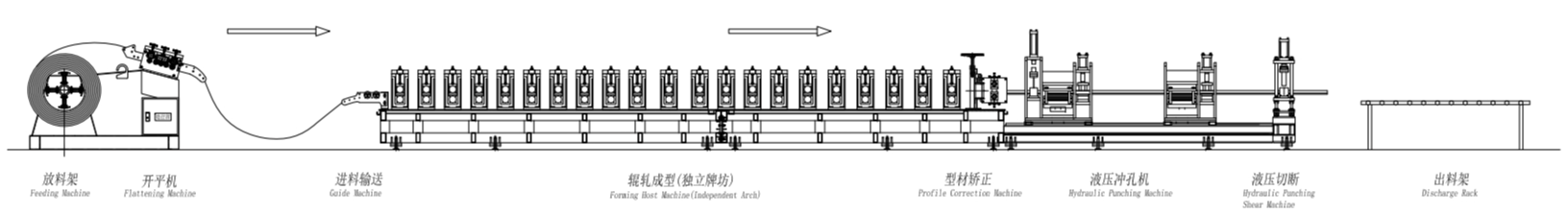

Principles of homework

After the roll material is fed, the door frame shape is formed by cold bending. After the forming is completed, various hole positions are formed by hydraulic stamping. Finally, the section shape and length output are achieved by hydraulic punching and shearing. At the same time, the entire line adopts a PLC control system, which can combine punching molds as needed, customize the door frame length as needed, select the punching and shearing section as needed, and one device can achieve the production of the upper frame/lock frame/hinge frame of the entire door frame (the material and frame shape of the lower frame can be consistent or completed synchronously).

Product features

● Fully automated homework, one click on/off, can be operated by a general worker, and computer ordering software can be configured as needed to achieve office ordering, with convenient operation and high degree of automation;

● All processes can be completed online without the need for additional turnover space or idle turnover, maximizing production efficiency and site utilization;

● The punching mold can be freely combined, and the cutting method can be freely combined. One device can complete the forming of the upper frame, hinge frame, and lock frame of the door frame without the need for additional equipment;

● Assembly line operation, mass production, has high production efficiency for mass production standard frames, and can also achieve frame shapes that cannot be achieved by some bending methods, with wide applicability;

● Forming first and then punching can avoid situations where some hole positions cannot be ● formed or the hole positions are deformed during the forming process after stamping; At the same time, forming first and then punching. When upgrading the production line of a single machine, the changes to the roller forming machine are minimal, making the transformation convenient;

Combination method

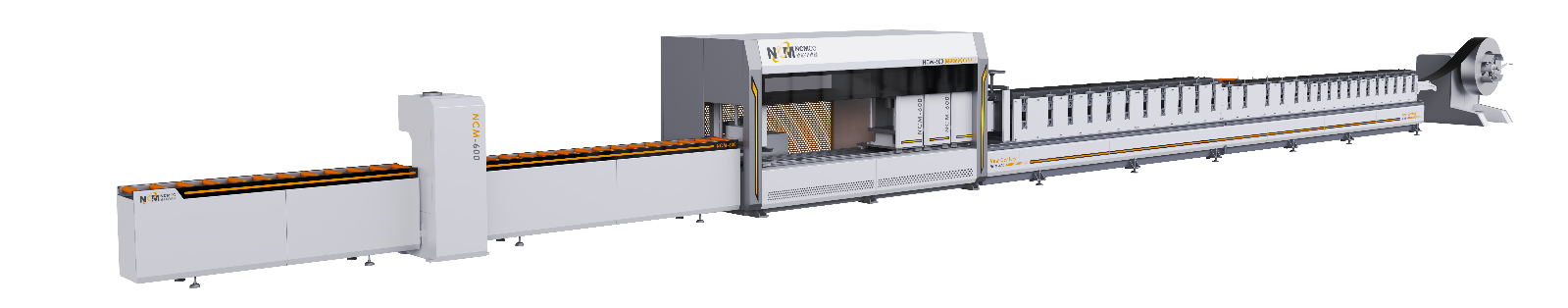

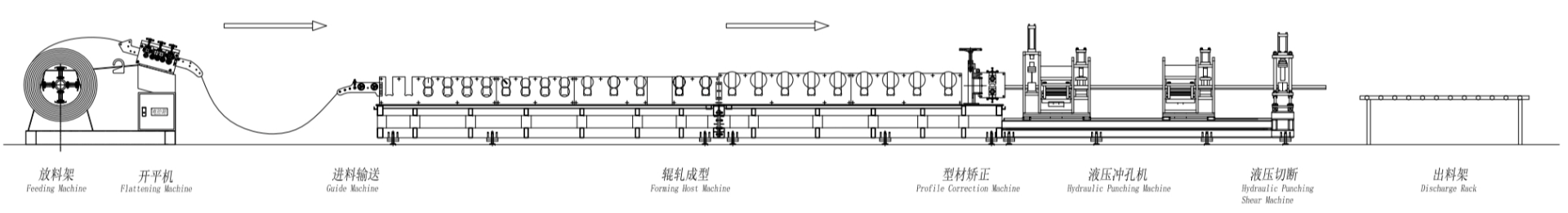

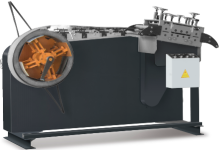

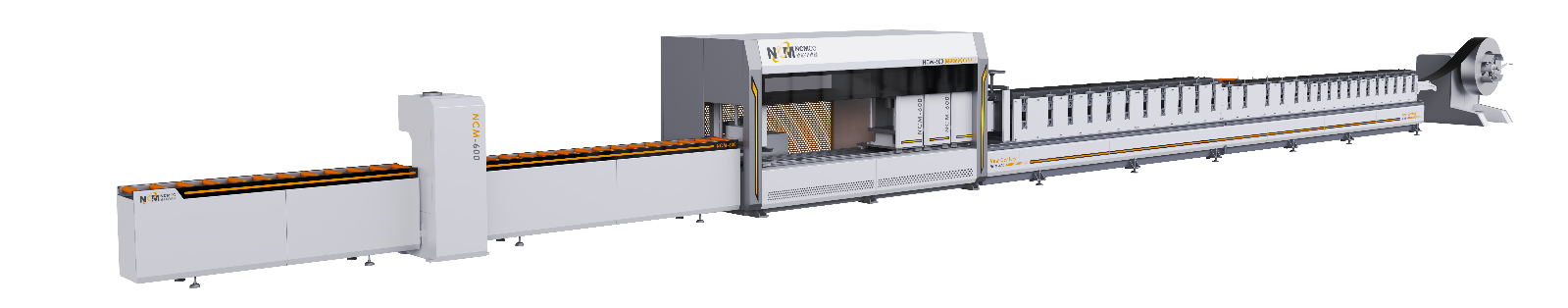

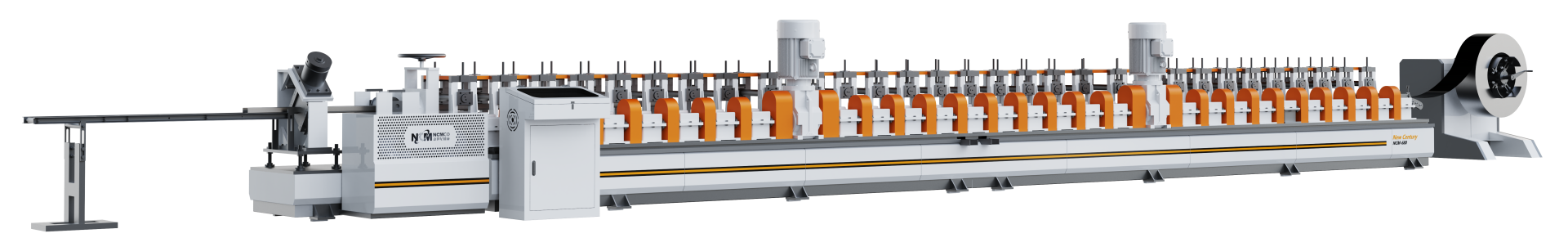

1. NCM-400 door frame molding machine as the molding host

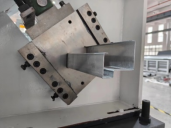

(1) Product images

(2) Production process

(3) Advantages of the plan

NCM-400 door frame molding machine serves as the main molding machine, with high cost-effectiveness and is suitable for most frame types;

(4) Technical parameters

|

technical parameter

|

Reference indicators

|

|

Feed plate thickness

|

(0.8-1.8) mm, customized according to customer needs

|

|

Feed plate width

|

(100-400) mm, customized according to customer needs

|

|

Production speed

|

(0-8)m/min

|

|

Total power

|

20-45kw, depending on product configuration

|

|

control system

|

Delta/Siemens, optional on demand

|

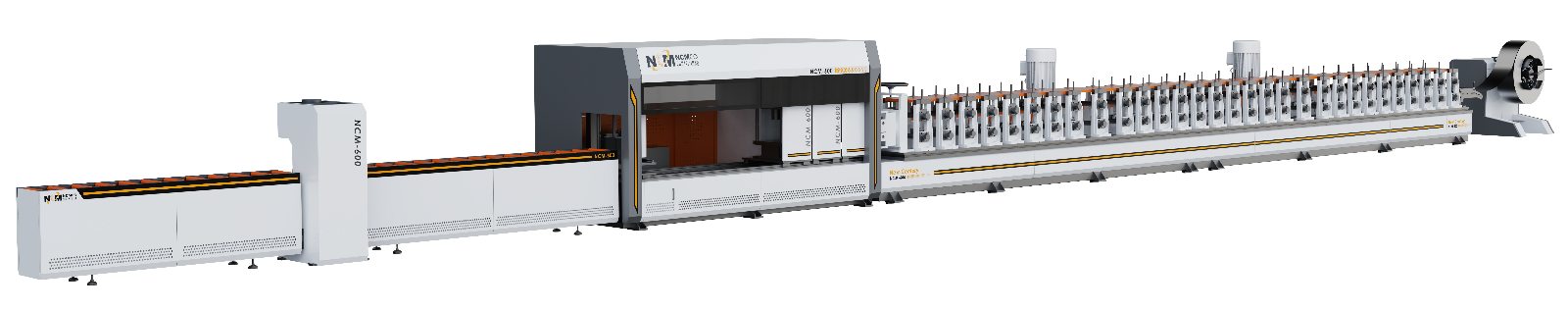

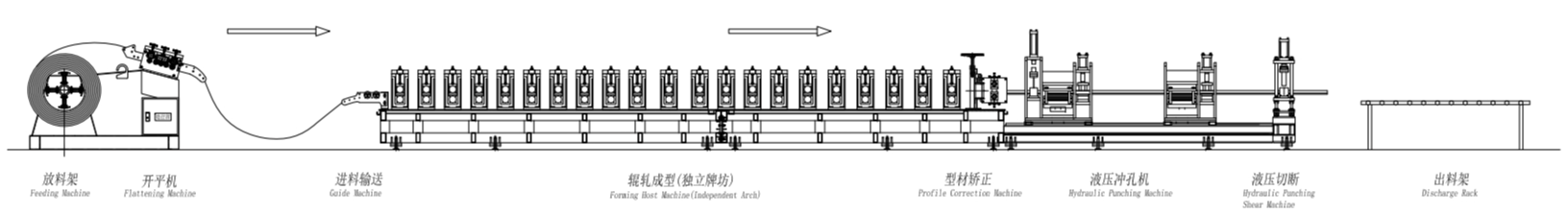

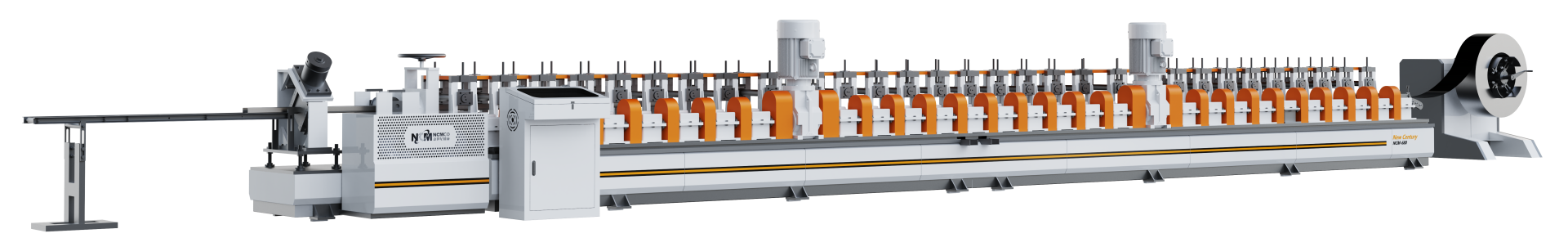

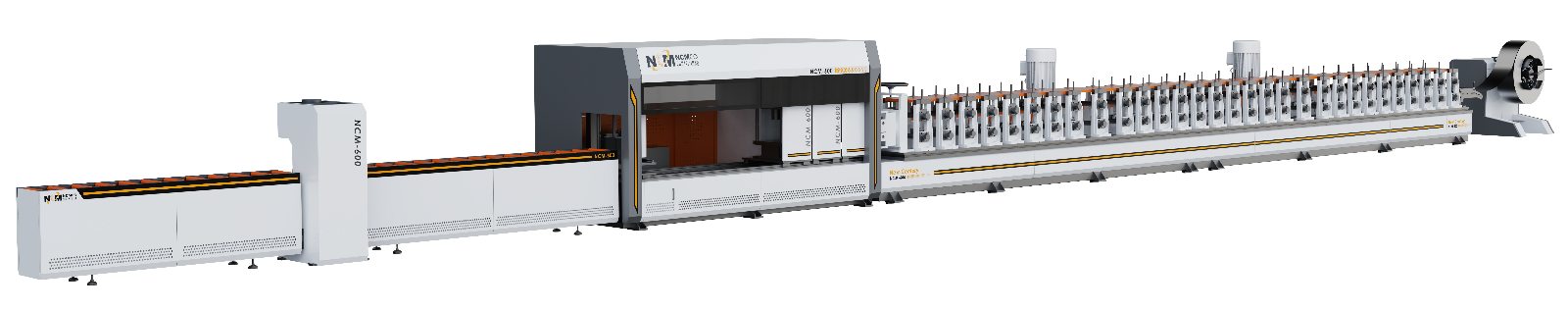

2. NCM-500D door frame molding machine as the molding host

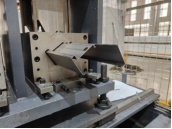

(1) Product images

(2) Production process

(3) Advantages of the plan

NCM-500D door frame molding machine, as the main molding machine, runs more smoothly and at a faster speed, suitable for thick plate production;

(4) Technical parameters

|

technical parameter

|

參考指標(biāo)

|

|

Feed plate thickness

|

(0.8-2.0) mm, customized according to customer needs

|

|

Feed plate width

|

(100-400) mm, customized according to customer needs

|

|

Production speed

|

(0-8)m/min

|

|

Total power

|

20-45kw, depending on product configuration

|

|

control system

|

Delta/Siemens, optional on demand

|

Detail display

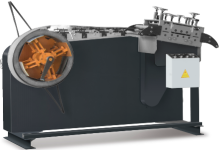

1. Material rack (standard configuration): used for placing coils;

● Equipped with a standard feeding rack, with a maximum weight capacity of 5T;

● The feeding rack adopts a hand cranked locking and buckle fixation method, providing dual protection to ensure that the roll material will not slip off;

2. Two in one feeding rack (optional): used for placing and flattening coils

● An optional two in one feeding rack can be equipped, with a maximum weight capacity of 3T;

● The feeding rack adopts a hand cranked locking and buckle fixation method, providing dual protection to ensure that the roll material will not slip off;

● Equipped with a leveling device, leveling can be completed at the same time as discharging to ensure the accuracy of subsequent processes;

3. Forming host: used for forming door frame shapes;

● Optional NCM-400 door frame forming machine, details can be found on the corresponding single machine page;

● Optional NCM-500D door frame forming machine, details can be found on the corresponding single machine page;

● Optional NCM-500D door frame forming machine, details can be found on the corresponding single machine page;

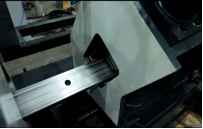

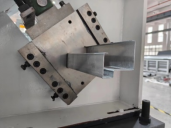

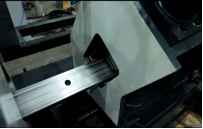

4. Rear punching machine: used for stamping the formed hole positions and cutting them according to length/section requirements;

● The stamping method adopts hydraulic pressure, with greater force and no burrs on the stamping surface. All hydraulic components are imported or domestic top brand products, which are durable and long-lasting

● Independent workstation with independent oil cylinder structure, each workstation can be independently controlled and can be combined for stamping as needed; Simultaneously independent oil cylinder ensures that if one oil cylinder is damaged in the future, it will not affect the use of other workstations;

● The punching molds are all made of Cr12Mov material, which is quenched and then processed by wire cutting. They are durable and easy to disassemble, making it easy to replace the molds as needed in the future;

● The cutting die is made of Cr12Mov material and processed by wire cutting, which fits the required frame shape and is durable; The cutting method adopts hydraulic pressure, with greater force and no burrs on the cutting surface; All types of hydraulic components are imported or international first tier brand products;

● Straight cutting knife (mainly used for flat cutting of door frame sections)/step knife (mainly used for forming door frame section steps)/circular saw (special process assistance) can be freely combined according to section requirements, and one machine can complete the production of the same frame type but different sections;

5. Electric control system: the control system of the entire assembly line;

● Whole line series connection, one click operation, convenient operation, and low demand for worker skills;

● Can preset production methods, flexible changes, suitable for various production needs;

● Independent research and development of new century machinery, perfectly matching the pace of equipment;

Random data and random attachments

1. Random data

|

Number

|

Name

|

quantity

|

Remarks

|

|

1

|

Shipping List

|

1 copy

|

|

|

2

|

Acceptance report

|

1份

|

|

|

3

|

User manual

|

1 set

|

|

|

4

|

Electrical schematic diagram

|

1 set

|

|

2. Random attachments

|

Number

|

Name

|

specifications

|

quantity

|

Remarks

|

|

1

|

O-ring

|

16*3.1

|

5 pieces

|

|

|

2

|

O-ring

|

20*3.1

|

5 pieces

|

|

|

3

|

O-ring

|

30*3.1

|

5 pieces

|

|

|

4

|

O-ring

|

32*3.1

|

5 pieces

|

|

|

5

|

Open end wrench

|

13-16

|

1 piece

|

|

|

6

|

Open end wrench

|

16-18

|

1 piece

|

|

|

7

|

Adjustable wrench

|

12*300

|

1 piece

|

|

|

8

|

Internal hexagonal wrench

|

1.5-10#

|

1 set

|

|

|

9

|

External hexagonal wrench

|

6-24#

|

1 set

|

|

|

10

|

Internal hexagonal wrench

|

12#、14#

|

1 piece

|

|

|

11

|

Cross screwdriver

|

|

1 piece

|

|

|

12

|

Small flathead screwdriver

|

|

1 piece

|

|

|

13

|

Directional solenoid valve 4WE10E

|

|

1 piece

|

|

|

14

|

Long zip ties

|

|

25 pieces

|

|

|

15

|

Open end wrench

|

41-46 (homemade blackened)

|

1 piece

|

|

The cooperation that the user should provide

1. Power supply: 380V, 50HZ, voltage fluctuation range from -5% to+10%; When there is a significant fluctuation in voltage, users must be equipped with a voltage regulator, otherwise it will cause low-voltage electrical appliances to be in an abnormal working state, reduce or damage the service life of electrical components, scrap processed products, motor alarm causing shutdown, computer hard disk damage, and other problems.

2. Gas source: Output 0.6Mpa or above, dry and clean compressed air, with a supply rate of 0.3 cubic meters per minute; If the air dryness is not sufficient, users should be equipped with a refrigerated dryer, otherwise there may be problems such as water ingress into the pneumatic components causing increased piston friction resistance, wear of the sealing ring leading to air leakage, especially in winter, which is prone to icing and exacerbates damage to the pneumatic components.

3. Environmental temperature: 0 ° C to+40 ° C; Below 0 ° C, it can cause components such as oil-water separators and air tanks that may contain water to freeze. Lubricating oil becomes too viscous due to low temperature, affecting lubrication effectiveness and leading to component damage or failure.

4. Environmental humidity: Relative humidity of 20-80% RH (non condensing).

5. Stay away from strong vibration sources and electromagnetic interference; If the distance is too close, the user must be equipped with a filter, otherwise it may cause problems such as computer screen flickering, LED flashing, driver alarm, encoder abnormality, or interference with other nearby devices.

6. An environment with little dust and no harmful or corrosive gases.

7. Do not cut off power while the equipment is in operation and maintain voltage stability.